Key Takeaways:

- Innovations in caster materials and design are boosting industrial efficiency.

- Ergonomic and safety-focused caster features are reducing workplace injuries.

- Integration of innovative technologies in casters is revolutionizing material handling.

Table of Contents

Introduction

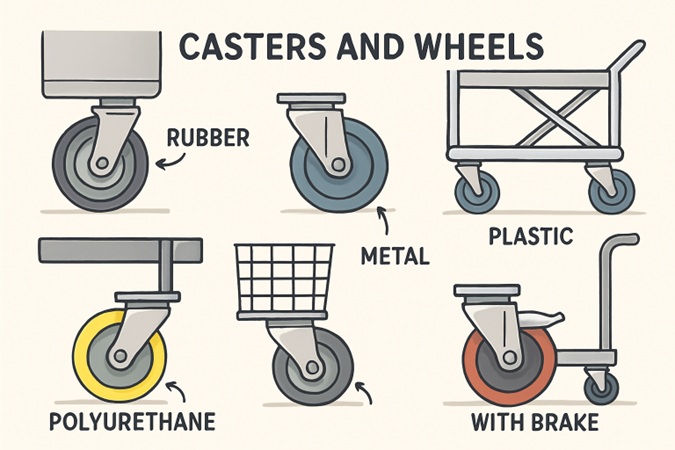

The world of modern industry is undergoing dynamic changes, with increased focus on efficiency, worker safety, and sustainability. Often overshadowed by larger machinery and systems, casters and wheels have silently become the backbone of these advancements. These components drive operational excellence by improving mobility, enhancing workflows, and reshaping material handling dynamics across sectors. Recent trends highlight the pivotal role that innovative solutions like shock isolating casters play in improving load stability, protecting sensitive equipment, and ensuring smooth transport even in demanding environments.

Casters and wheels have evolved from basic utility components to high-performance tools integral to diverse settings—factories, warehouses, hospitals, and laboratories. Material science and design developments have led to more durable casters better suited to today’s fast-paced, safety-conscious workplaces. These advanced casters improve productivity by reducing the energy required to move heavy objects, minimizing noise, and mitigating vibration-induced damage that can compromise machines and materials.

As businesses strive to optimize logistics, supply chain operations, and employee well-being, specialized caster solutions have become vital to their strategic toolkit. Enhanced ergonomic features now help reduce workplace injury risk, while innovative technologies connect casters to the digital industrial ecosystem. In this way, even a minor upgrade or adopting a specific caster technology can yield measurable improvements in efficiency and cost savings.

These advancements open new possibilities, empowering industries to respond swiftly to operational challenges, supply chain demands, and evolving safety standards. For example, the rapid growth in e-commerce and on-demand delivery services has fueled the need for lighter, more robust caster solutions tailored to ever-changing load needs and facility layouts.

Advancements In Caster Materials & Design

Modern casters benefit from engineering breakthroughs in materials science. High-grade polyurethanes, reinforced nylons, and thermoplastic elastomers have replaced traditional rubbers and plastics. These advanced materials are designed to endure harsh environments, resist chemicals, and operate smoothly under extreme loads. Notably, engineered polymers used in many industrial casters now provide up to 18% less friction, translating to less floor wear, greater energy savings, and less operator effort. This new generation of casters also excels at dissipating heat and reducing noise, which are highly valued features in warehouses and healthcare environments where both stealth and performance are critical.

Ergonomic Designs Enhancing Workplace Safety

Worker safety and ergonomics are more critical than ever. Advanced caster features like shock absorption, directional locking, and easy-swivel mechanisms are designed to reduce the force needed to move heavy loads, preventing muscular injuries and repetitive strain. According to recent industry data, facilities that upgrade to ergonomic casters have reported a 27% gain in order picking efficiency alongside a notable reduction in workplace injuries related to material handling. Enhanced stability, improved braking systems, and smoother rides ensure worker health and the integrity of transported equipment and goods.

Integration Of Smart Technologies

Smart casters equipped with sensors and wireless connectivity are transforming material handling. Integrating IoT and AI, these systems continually monitor load weight, movement patterns, and environmental factors like temperature. Real-time data enables predictive maintenance, alerts operators to unsafe conditions, and minimizes downtime due to caster failure. AI-powered solutions further optimize equipment routing and can help prevent collisions. The ability to monitor and react to changing conditions propels the caster industry into the era of intelligent logistics with modern Industry 4.0 initiatives. For more information on how smart factories leverage digital advancements, visit McKinsey Digital Manufacturing Insights.

Customization For Industry-Specific Needs

Manufacturers now recognize that one size does not fit all, especially regarding casters and wheels. The pharmaceutical industry relies on anti-static casters to prevent contamination and protect sensitive equipment. Food service and healthcare sectors frequently use sealed, stainless-steel casters for hygienic, washdown-safe operations. Heavy manufacturing industries require rugged, oversized wheels to navigate uneven floors and support extreme loads. This industry-specific customization maximizes productivity and ensures stringent compliance with safety and quality standards. See this Supply Chain Digital article for a deeper understanding of how tailored mobility solutions are reshaping logistics.

Market Growth & Future Prospects

The global market for casters and wheels is growing at an impressive pace, fueled by escalating demand for mobility solutions across manufacturing, warehousing, and healthcare settings. Projections indicate the sector could reach $9.9 billion by 2025 and expand to $23.7 billion by 2035. Industry players attribute this surge to technological innovation, population growth, and increased automation—all of which require agile and adaptable mobility solutions. The significant capital flowing into R&D signals that next-generation casters will be even smarter, sustainable, and capable.

Environmental Considerations & Sustainability

The push for eco-friendly practices is reshaping caster manufacturing. There is a growing trend towards incorporating recycled plastics, renewable feedstocks, and biodegradable compounds into caster production. Additionally, modular caster designs mean worn parts can be replaced individually rather than disposing of the entire unit, reducing landfill waste. This commitment to sustainability appeals to companies under regulatory and consumer pressure to green their supply chains and reduce carbon footprints. Environmental best practices for industrial machinery are becoming the norm as industries strive to achieve their ESG targets.

Conclusion

Casters and wheels transform modern industry by driving efficiency, championing safety, and elevating sustainability standards. As materials, designs, and technologies evolve, these foundational components will continue to unlock new levels of performance, supporting a future where safety, productivity, and environmental stewardship go hand in hand.

No Comments